Process Monitoring (WaSP)

JRP's 'WaSP' POS solution provides opportunity for minimizing cost, maximizing throughput, and increasing efficiency through enhanced data capture, visualisation and reporting allowing enhancements to be easily made to process control functionality within wastewater process management and sludge production.

Control & Monitoring Applications - The WaSP POS product range provides a control and process monitoring device which can be deployed as a multiple ‘one stop' solution for new build or retrofit environments. Current standard software module applications include: -

- Automatic Decant - Control decant valve operation based on optimal solids / flow parameters

- Automatic Desludge - Control desludge pump operation based on optimal solids / flow parameters

- Digested Performance Monitoring - Capture digester flows, solids and temperature readings

- Chemical Dosing - Optimise and control the dosing process for a particular application

- Belt Press Thickening Lines - Monitor the thickening / dewatering process and improve efficiency

- Sludge Tank Export - Monitor & control liquid sludge export process to road tankers

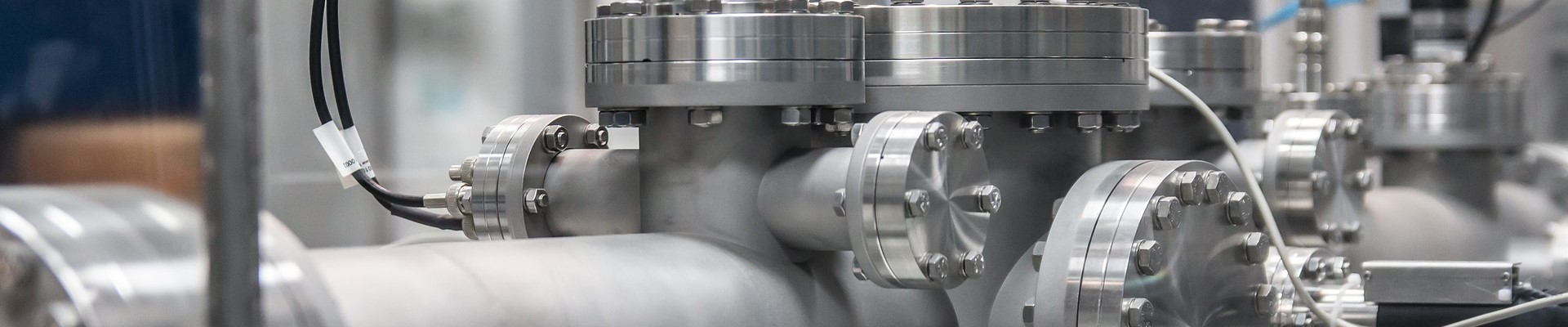

Operation - The 'WaSP' POS solution can be integrated with a variety of standard process instrumentation such as flow meters, suspended solids metering, pH monitors, temperature sensors, level detectors, etc. as well as actuated valves and pump controls for diverting flow, auto decant or desludge operations, etc.

Operation - The 'WaSP' POS solution can be integrated with a variety of standard process instrumentation such as flow meters, suspended solids metering, pH monitors, temperature sensors, level detectors, etc. as well as actuated valves and pump controls for diverting flow, auto decant or desludge operations, etc.